Untouched World was born out of a desire to make a positive impact in the world. There is a lot we can do on our own as a brand, from employing skilled local makers from within our community to ethically sourcing natural fibres that are easy on the earth, but we also acutely understand the need for collaboration and cooperation to spread our impact as broadly as possible, as well as amplifying the impact of others.

That’s why we’ve proudly partnered with Outland Denim, a fellow B Corp which makes high quality denim with a human-centred approach. Lucy High Rise, Athina Mid Rise Boyfriend Jean and Ellie High Rise Wise Leg Jean are now available to buy online and instore at Christchurch and Wanaka. We’re thrilled to share our platform with a brand whose values align so closely with ours.

Allow us to introduce you…

What’s the story?

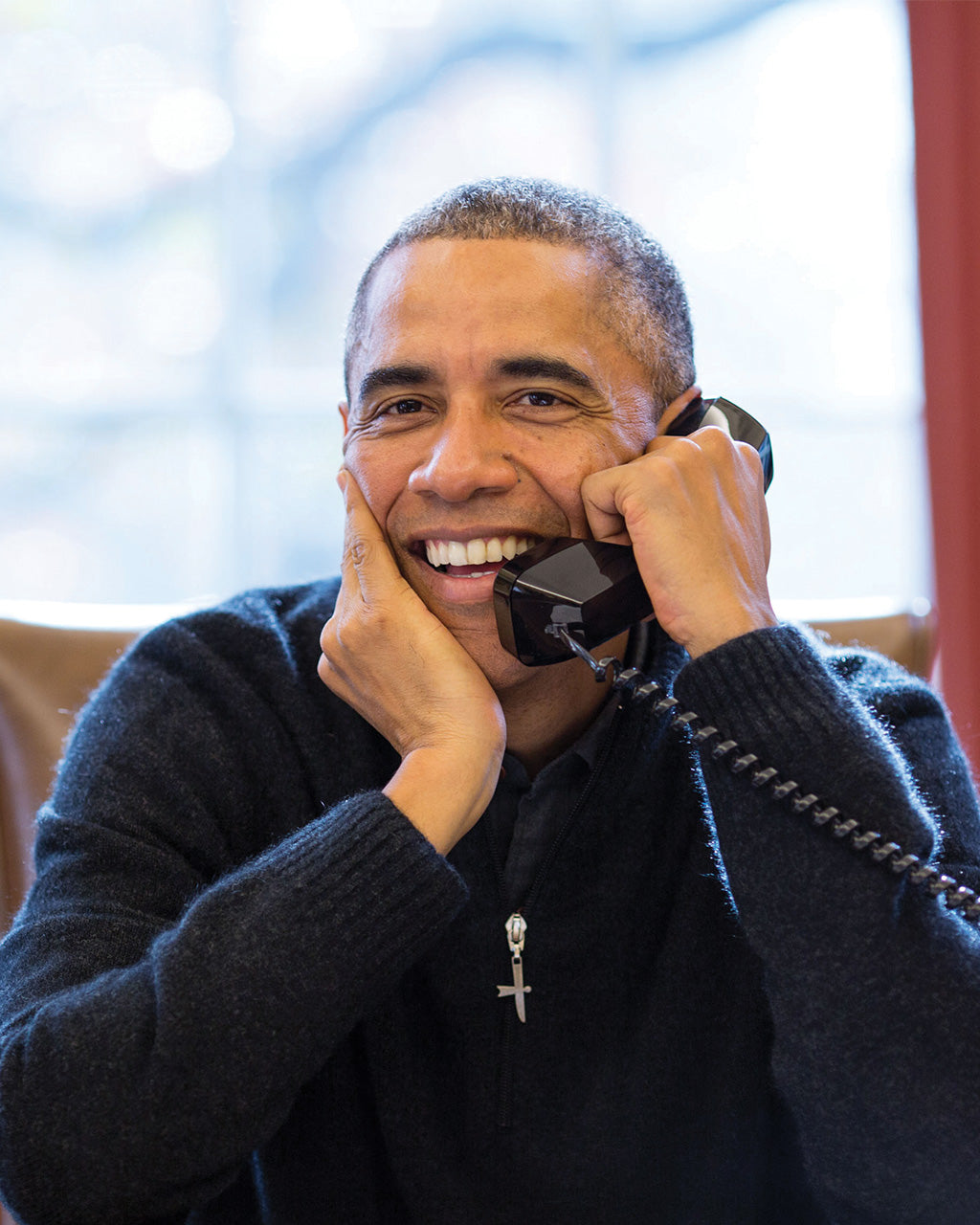

Outland Denim was founded in 2011, with a vision of becoming a safe haven for survivors of sexual exploitation. The idea was sparked after founding CEO James Bartle watched the film Taken, which focuses on kidnap and human trafficking. Although a fictional film, it was a reflection of a serious reality, and it stayed with Bartle. “It was a very confronting film… I remember leaving the cinema that night feeling outraged by the fact that these kinds of events still happen around the world,” he says.

A research trip with a rescue agency solidified Bartle’s feeling that he had to do something about the global issue and a few years later Outland Denim was born. Since those early days, the brand has widened its scope to welcome survivors from “varying backgrounds of vulnerability and exploitation” but the mission remains the same: manufacturing Outland garments provides stable, dignified employment as a means for people to rebuild their lives.

Outland’s garment makers are trained over the course of two-three years in every element of the jean-making process across cutting, finishing, and sewing. They are paid a living wage to ensure a good standard of living, and have access to education and personal enrichment such as budgeting, infant health, computing skills, and English. 70% of the Outland Denim production team had to stop their studies during primary or secondary school but now 98% of them share their education with their families and communities, spreading the positive impact. To date, more than 750 people have benefited from stable employment at the brand.

Protecting people and planet

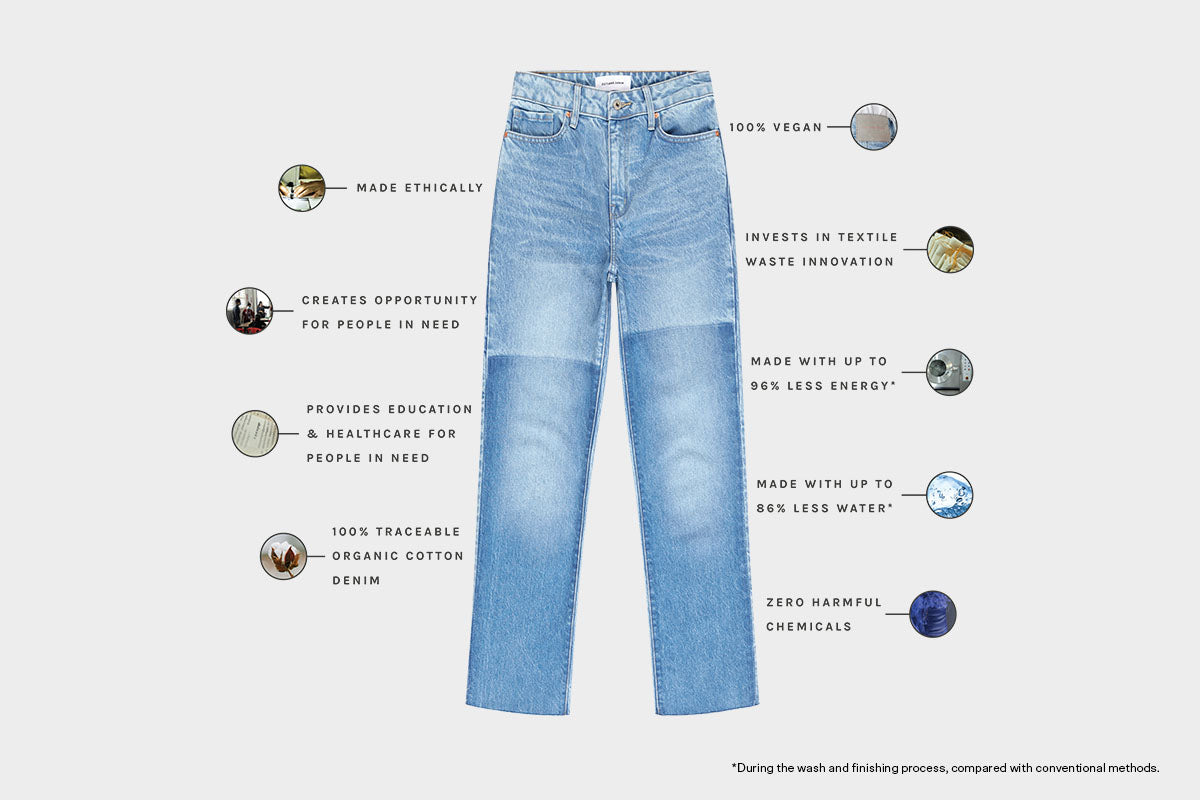

Providing survivors of exploitation with work and training on the one hand while compromising their future with unsustainable practices on the other would be counterintuitive to say the least, so Outland Denim aims to “clean up the dirty side of denim” too.

The estimate for the number of pairs of jeans made every year vary from two billion to five billion. A difference of three billion is, of course, huge, however anything manufactured in its billions – whatever the exact figure – is on course to have significant environmental impacts and these impacts can occur at many different stages. Harmful chemical fertilisers and pesticides can be used during the cultivation of the cotton used to make denim, a great deal of water can be used to process the cotton, and toxic dyes can be used to dye the garments. Synthesising indigo (the traditional pigment used to colour denim) requires the use of a number of different toxic chemicals including formaldehyde. In addition, some jeans are sandblasted in poorly ventilated conditions to create a vintage look, while others are subjected to chemical or acid processes to ‘age’ them.

Outland Denim has no intention to continue harmful practices in its supply chain, opting to use innovative new technology by Jeanologia to reduce water, energy, and chemical consumption. E-Flow technology allows the brand to finish its garments safely with fewer chemicals. Using lasers means the brand can add character such as fading and whiskering without hazardous chemicals or sandblasting, and ozone technology can create a bleached, worn effect without resorting to chemical bleach or stonewashing (popular in the 80s) which requires multiple washes and rinses.

Each option results in specific impact reductions as high as 90%, and the overall average water saving for the brand is 60% compared to conventional denim manufacturing according to the brand’s 2022 impact report. Outland is also working on reducing its footprint elsewhere in the business, reporting a 36% reduction in brand carbon emissions each year. This no-stone-left-unturned approach mirrors our own.

“Outland Denim is built on a business model that gives instead of always taking. We exist to uplift the people who make our garments and to protect the planet we share. No smoke. No mirrors. No greenwashing. Just impact.”

Natural fibres

Denim is traditionally made from cotton, but mixing in synthetic fibres has become the norm to add stretch and keep costs down. However, much like us, Outland Denim is committed to using natural fibres wherever possible, and is reducing the small amount of synthetic fibres it does use. Its raw material breakdown is 1% hardware (zips, rivets etc), 6% synthetics, and 93% natural fibres, and it increased its use of natural fibres by 8% between 2021 and 2022. Of those natural fibres, 77% of Outland’s production volume is GOTS Certified Organic Cotton.

Other natural fibres and materials that Outland Denim uses includes Lyocell (a wood pulp-based fibre made in a closed-loop system), BCI cotton, which is grown to certain environmental and social standards, linen, and corozo nut buttons.

Transparency

We have nothing to hide, and we’d expect nothing less from our partners. Outland Denim discloses its supply chain right back to who it sources its cotton seeds from. Owning its own manufacturing facility certainly makes it easier to know exactly who is making its clothes and how much they’re getting paid, but it does work with other suppliers across Turkey, China, Vietnam, Cambodia, India, Lithuania, and Australia, too, listing them publicly, along with what they make and their certifications and standards. If you want to see all the details, you can dig into them here.

B Corp partnership

At every stage of its manufacturing process, Outland Denim seeks to positively impact the planet and the people who work for it, so it’s perhaps no surprise that it became a B Corp in 2018, making it the first Australian denim brand (and second globally) to achieve certification. In 2023, it achieved its highest score yet, demonstrating that it’s not a brand to rest on its laurels.

All of this, and Outland makes beautiful, timeless high quality denim pieces that will outlive trends to become wardrobe mainstays. We couldn’t ask for much more from a partner.

Shop Outland Denim on Untouched World here.

To learn more about denim:

-

Read: Unravelled: The Life and Death of a Garment, by Maxine Bedat

-

Watch: The Tiny Bubble Secret to Sustainable Denim Jeans, by Bloomberg

-

Listen: How Outland Denim built a social impact brand, by Growth Manifesto