Our use of natural fibres for sustainable design is woven into our DNA. We say that doing right by people and the planet is business as usual for us, and that starts with selecting fibres and fabrics that are easy on the earth. We use beautiful merino, possum blends, silk, cashmere, organic cotton, and plant-based fibres such as linen, aloe vera, TENCEL™, and even soybean, all of which are cultivated responsibly and which will return to the earth as nutrients at the end of their life, when composted.

Currently 93% of our products are made from 100% natural fibres. So, while we use all natural fibres wherever we possibly can, 7% of what we make contains a small amount of synthetic fibres like Lycra, elastane, or nylon, added for stretch or performance, or derived from the deadstock fabrics we source.

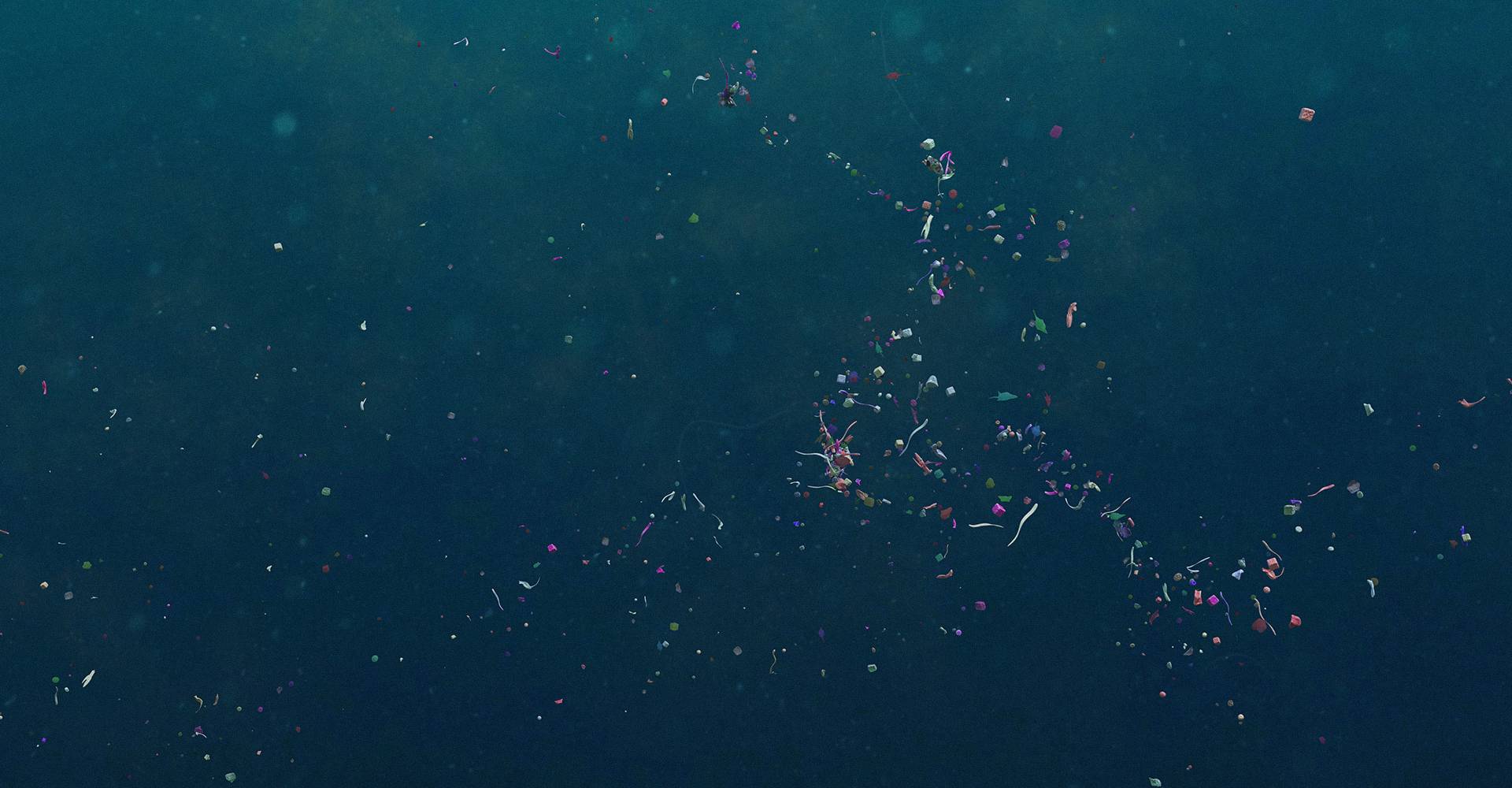

93% is a high percentage and we know some might just sit happily with that figure, but we’re always looking for ways to improve, even within the tiny percentages. We don’t want to stand still, so we’ve made a commitment to reach zero microplastics by 2030. As we talked about in our piece on plastic’s position as fashion’s go-to fibre, the impact of synthetic fabrics and the microplastics they shed can’t be overlooked. A 6kg load of washing can shed over 700,000 plastic microfibres and, unsurprisingly, microplastics from synthetic clothes are the biggest single source of microplastic release into our oceans, contributing a huge 35%. We don’t want to contribute to this pollution so we’re on a mission to reach that zero microplastics figure by 2030, and here’s how we’re going about it.

Transparency

Transparency is the key to ethical fashion because the more information a brand shares, the more they can be held to account. We disclose information about everything from our suppliers to our energy use, our waste, and our partnerships, so it makes sense that we’d be open about our fibre mix too. By sharing that 93% of our products are made from 100% natural fibres, we tell you what our starting line is, so you know what progress we need to make. But we go beyond that too.

Back in November, we shared our discovery that there is 20% nylon in our Ecopossum and Rubbish socks. We could have kept this to ourselves, but we think it’s important to be honest about everything – even the things we’re disappointed about.

We send our 100% natural yarn blend to our sock makers (who we’ve worked with for over a decade) to turn into socks because we don’t have the machinery to make them here in our onsite workrooms. We thought that just a tiny percentage of elastane was added around the top of the socks to keep them from slipping down, but in November we learned that the nylon was actually knitted throughout the sock to make it more durable.

Of course, this is frustrating, but it’s also another challenge that we can tackle and in being transparent about it, we can bring you along on that journey with us.

Innovation

Going microplastic free isn’t as simple as just removing synthetic fibres. Whether we like them or not, we do understand that synthetics like nylon and polyester can add certain performance benefits like stretch and durability so we need to find other ways to add these properties to our garments.

Take our socks, for instance, it turns out that the 20% nylon blend was to create a more durable sock that would last much longer. If we simply remove it, there is the possibility that our socks won’t last very long, and that’s not how we want to design. So, we’ve started sampling. We’re trialling nylon-free socks as well as socks that have nylon in the heel and toe only, areas of high wear and tear. At the same time, we’re looking for new fibres that could replace nylon entirely and are more aligned with our approach to environmental stewardship. We are so grateful for all the people within our community that have made suggestions for alternatives to Nylon, that we are currently investigating.

There are lots of exciting new fibres out there and we’re on a mission to discover clever natural alternatives to nylon and the other synthetics that feature in a small percentage of our clothes. From there, we can assess sustainability, do tests, make samples and trial pieces, and – hopefully – start adding the alternatives to our full collection. It will be a long process with lots of imagination and innovation needed, but we’re committed to working towards our goal.

Keep an eye on our social media and journal for updates along the way.

To learn more about microplastics: